Miniaturization and cost effective manufacturing capabilities that were never possible before now are in real industry. However, commercially available MEMS products have only scratched the surface of the application areas where MEMS has big potential. The complex and highly technical nature of MEMS research and development (R&D) combined with the lack of standards in areas such as design, fabrication and test methodologies, makes creating and supporting a MEMS R&D program a technological challenge.

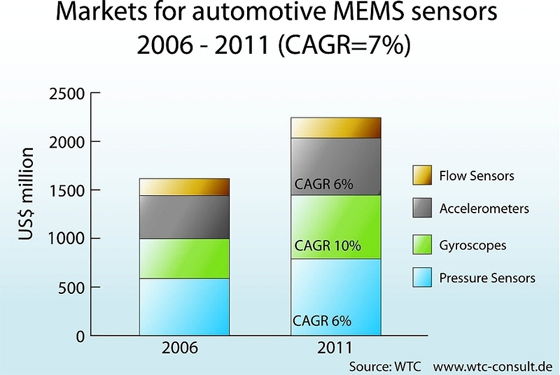

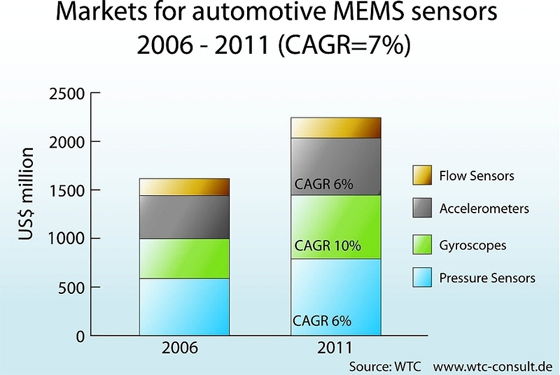

To ensure these microstructures perform reliably in their operating environments, MEMS engineers must rely on FEA simulations, determines stress, deformation, resonance, temperature distribution, electromagnetic interference, electrical properties and fluid-flow (CFD). Thermal and CFD analysis can determine the heating of solids and fluids in MEMS devices that are used in electronic circuits. With electromagnetic analysis, engineers can calculate electrical and magnetic field activated forces needed for small switching devices. The IT and automotive sector has long been a growth markets for MEMS sensors, as shown in a chart below. For an instance today's high-end vehicles feature up to 100 different sensors. About 30 these are now MEMS. The market is made up of accelerometers, gyroscopes and inclinometers as well as pressure and flow sensors. Emerging applications include IR sensors for air quality, microscanners for displays and, further out, MEMS oscillators and energy recovery systems.The figure below shows increasing share of MEMS in industry for 2006 as well as predicted values for 2011: